Direct Drive Rotary Table

The DMT direct drive rotary table is divided into four axis rotary tables and five axis rotary tables,according to the purpose of the machine tool spindle. According to the working direction, it is divided into vertical and horizontal rotary tables. According to the processing speed, it is also divided into high-speed rotary tables and ordinary rotary tables.

The rotary table benefits from DMT's leading direct drive technology, with advantages of high speed, high precision, and low maintenance costs. The positioning precision can reach ± 3 angular seconds, and the repeated positioning precision can reach ± 1 angular seconds. The standard acceleration is 1G, up to 5G, and the 90 degree reciprocating positioning can reach 1200 times/minute.

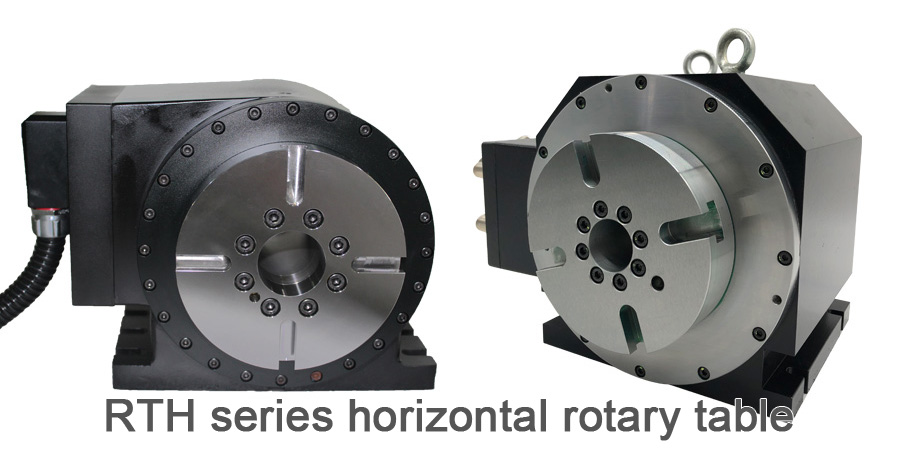

RTH series horizontal rotary table

RTH series CNC horizontal direct-drive rotary table adopts a high dynamic response direct-drive motor, eliminating problems such as wear, clearance, elasticity, and hysteresis caused by transmission components. It is mainly used in machining centers and other machine tools as a horizontal fourth axis to achieve such functions as polyhedral indexing processing (such as opening holes in the outer frame of mobile phones), and curved surface linkage processing (such as spiral grooves)

RTV series vertical rotary table

RTV series CNC vertical direct-drive rotary table adopts a high dynamic response direct-drive motor, eliminating problems such as wear, clearance, elasticity, and hysteresis caused by transmission components.

It is mainly used as a vertical fourth axis machine tool for machining centers, or as a multi station continuous machining indexing rotary table.

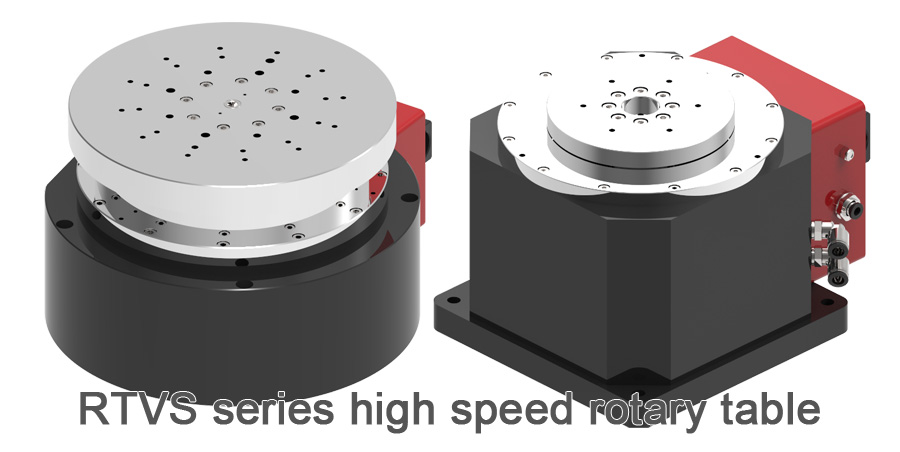

RTVS Series High Speed Direct Drive rotary table

The high-speed vertical rotary table can meet the needs of high-speed machining.

RTMS Series Single Arm Five Axis rotary table

High acceleration, high torque, high precision, zero backlash, built-in air pressure powerful braking system, using large aperture, high rigidity bearings. Mainly used in machining centers and other machine tools, pentahedron machining, curved surface machining (such as spiral blades).

RTMS series 5-axis cradle rotary table

Based on advanced design concepts, the cradle type dual axis linkage direct drive CNC rotary table adopts a torque motor direct drive scheme, which has the advantages of fast response, high precision, and convenient maintenance. The efficient and simplified braking scheme ensures reliable operation, while achieving a tight rotary table structure; At the same time, according to customer needs, we provide options for motors, bearings, and circular gratings that are suitable for different use scenarios, maintaining the highest cost performance while satisfying the use requirements.